Innovation steeped in tradition.

Masterful craftsmanship

Exquisite woods and metals come together to form a MIYABI knife. With over 100 production steps, it takes months to reach this level of mastery. We deliver only the best, just for you.

The desire for more.

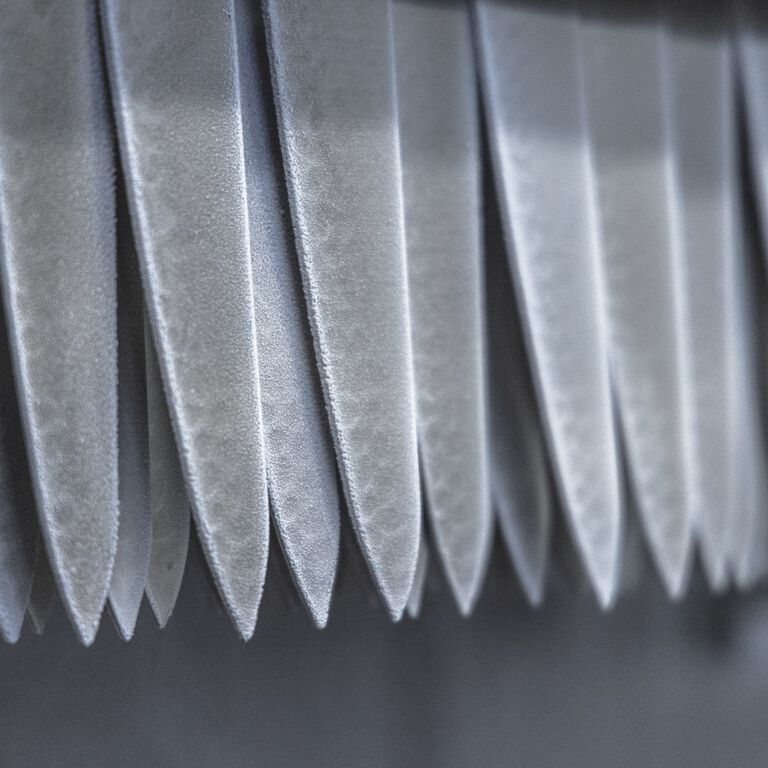

For our knives, we use specially selected steel grades with one thing in common: their high hardness levels of 60 HRC and higher. We use up to 133 layers of steel in the production of our knives to create masterpieces of hardness and sharpness for you.

When excellence merges with perfection.

Artful folding and merging of multiple layers in blistering heat, the blade core gently embedded. The art of rolling and sandblasting transforms once straight lines into captivating motifs. A unique feature of this manufacturing method lies not only in the patterns of the blades but in the careful multi-layered structure that protects the precious blade core. It is exposed only at the cutting edge to prevent corrosion and breakage and to ensure the balance between durability and sharpness.

A legend of fire and ice.

MIYABI knives are ice-hardened immediately after forging. The blades are cooled down to the lowest temperatures and hardened. The result is the special CRYODUR blades, the ideal combination of outstanding hardness, flexibility, and corrosion resistance.

Perfection. Masterfully sharpened.

The traditional Japanese Honbazuke honing method, translated as “true edge”, is the final grind that gives our knives the outstanding sharpness for which they are renowned. It requires an in-depth understanding of the knives, their characteristics, and the precise 10° angle to achieve this sharpness at the highest level. Only five carefully trained craftsmen and women master this skill at MIYABI. Not only have they spent over five years learning it they have also sharpened more than a million knives. Tireless dedication and the preservation of ancient tradition combine to accomplish excellence.

Charcteristics of excellence

The high-quality MIYABI knives are made of carbide steel, a high-quality compound composed of tungsten and carbon.

STEEL

Fine Carbide (FC)

Fine carbide steel, known for its unparalleled hardness and durability, gives MIYABI knives their wear resistance. This steel, characterized by a fine carbide structure, ensures lasting sharpness. The FRIODUR blade has undergone ice hardening twice.

Micro Carbide (MC)

In the world of MIYABI, micro carbide steel takes the throne of extraordinary sharpness. Here, the knives bear the brilliance of the finest carbide particles, artfully fused by masterful skill. Their impressive structure takes cutting performance to a new level.

FINISH

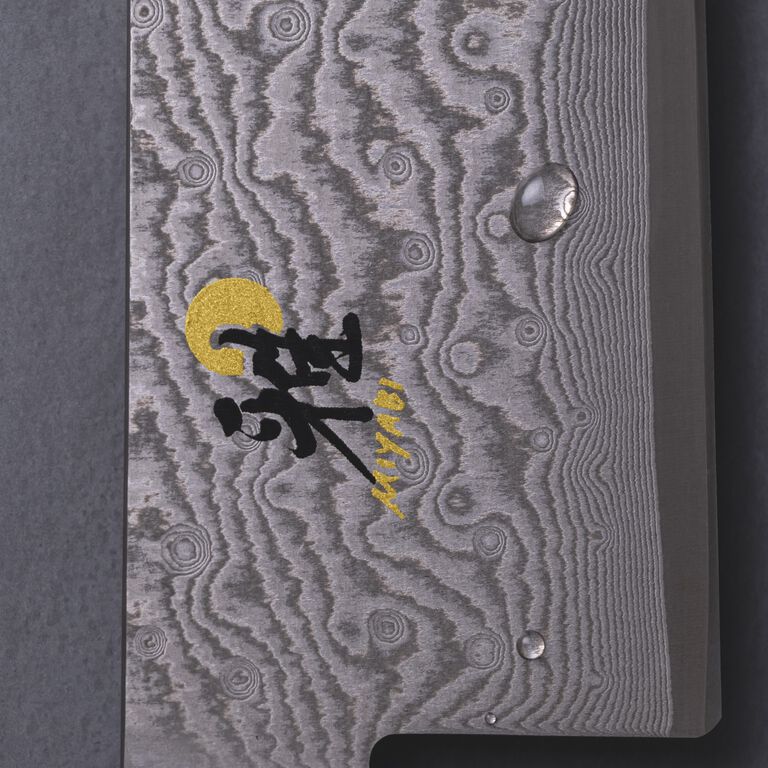

Damast (D)

Damask is a testament to traditional Japanese knife culture. Each Damascus finish, in which the layers of steel interweave, is unique. The elaborate process gives knives a captivating aesthetic and makes the blade more resistant. A promise of countless outstanding culinary moments.